Banana stems can be turned into useful resources in the manufacturing industry. Ugandan company Texfad uses banana stems in making various products like fabric. The waste stems can prepare fiber cloths, rugs, and even hair extensions. The company is still working on its expansion.

The evolution of TexFad

After graduation, Kimani Muturu was unemployed. Out of hard life, he came up with the idea of using the turning the banana stems into beneficial products. They can make good quality manure, but they are too much in Uganda. The worst part is that the stem cannot bear again once it rots.

He started Texfad in 2013 as a personal project. After making various materials like rugs, he employed some young people. They then came up with more ideas to extend the products other than just rags.

What is the preparation process?

The chunks dry together for a specific period. Then we have an extractor where they are fed into. The extractor costs too much, between $1000 – $10000 per machine. The machine divides the chunks into small thin pieces, which are then dried. When they feel like silk, it means they are ready for weaving. Household craft is the next process done by a few creative women, a report by The Insider.

The company is still small with 23 employees, but it keeps on growing daily. The Business Insider reporter meets Timusijime Moses, the Banana coordinators. He says the country has millions of unemployed graduates. The truth is the government cannot provide jobs for everyone. This is the reason they take TexFad as the next big thing that could offer employment to many youths. He has faith that the company will expand its roots to the rest of the world.

East African culture contributes a lot to the process. Furthermore, ideas are being awakened to create useful products that are helpful to society. Utilization of the available resources is the economic goal for any country.

Esther Ainebyoona, a weaver, also talks to a Business insider. The lady praises their team for the cooperation and motivation they share. She talks about teamwork in the company and how everyone’s idea is useful.

Also Read: Subway to Stop Using Artificial Ingredients

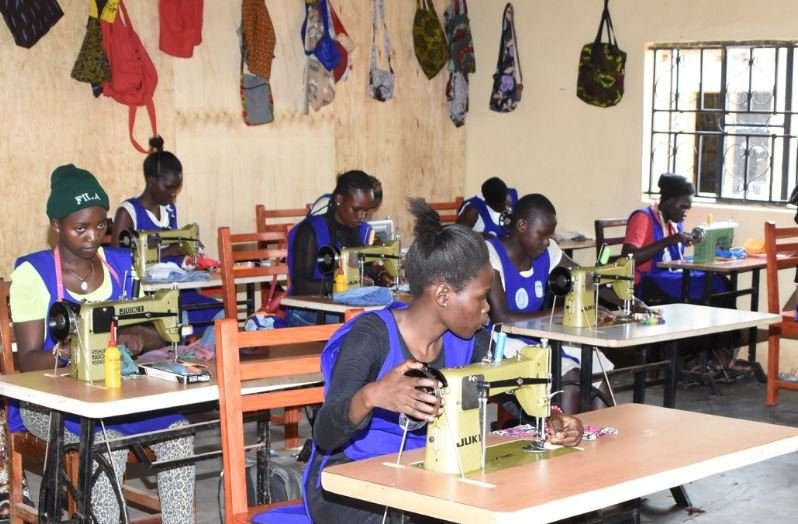

Various people are dealing with different categories of jobs. Those employed in the weaving section to prepare the final product. We have those with the knowledge of using the extractor. These individuals make sure that the chopping process gets complete. Some people will carry banana waste from the land and ensure they are at a central location for drying. The team has good communication skills.

Workers weaving inside Texfad- Courtesy of Texfad

Plenty of raw-materials

The raw materials will never run out. Bananas are the staple food for Ugandan people. Almost 9,000,000 tonnes of bananas are used in a single year. Other top producing countries are Japan and the Philippines. The idea is still concentrated in East African countries, a report by Interesting Engineering.

Leonie Haakshor, the Rainforest Lead, says that the fruit stem provides perfect manure. Furthermore, it produces water which then prevents deforestation. In addition, the chunks can produce fertilizers when taken to factories again.

The banana chunks rot faster and easier. Likewise, banana fiber absorbs water quickly as compared to fiber. The amount of water used is also minimal. Learning about the preparation process takes a short time, a report by Kimani, the CEO.

Disadvantages faced by Texfad

However, the main disadvantage is that the extraction machines are not fully developed. They are doing more work using human power. They are still in negotiations to acquire other extractors to expand the business. Kimani has faith that banana silk is the next big thing in the clothing industry.

TexFad industry will expand its roots across the world, if not in Africa. Who hates a naturally made cloth from fresh raw materials? Besides, cotton fiber is becoming exhausted, and banana waste seems to be the next successor. This will improve the country’s economy if there is mass production. This will result in exporting hence countries earning higher foreign income. The Third World countries are doing what they can to cope up with the first-world countries. Everyone has the potential to be innovative.

Comment Template